Company

Outline

| Name | EPSON ATMIX Corporation |

|---|---|

| Address |

Headquarters 4-44 Kaigan Kawaragi Hachinohe Aomori 039-1161 Japan Kita-Inter Plant 2-1-60 Kita Inter Kogyo Danchi Hachinohe Aomori 039-2245 Japan Kita-Inter Plant No.2 4-3-28 Kita Inter Kogyo Danchi Hachinohe Aomori 039-2245 Japan |

| Establishment | October 1, 1999 |

| Capital | JPY450 million |

| Shareholders | Seiko Epson Corporation |

| Solutions | ・Metal powder ・Metal injection molding components ・Synthetic quartz crystal |

| Bank |

Mizuho Bank Aomori Michinoku Bank |

|---|---|

| Fiscal year end | March |

| Board members |

Chairman Isamu OTSUKA President Ryo NUMASAWA Directors Kiyokazu NAKAMURA Koichi OSHIMIZU Masayuki YONAI Auditor Yoshihiro MIZOGUCHI |

| ISO acquisition |

・ISO9001 - Certificate download ・ISO14001 - Certificate download ・ISO45001 Scope of Certification - Headquarters - Kita-Inter Plant |

History

| October 1999 | Established with the full amount investment of Seiko-Epson Corporation. |

|---|---|

| March 2001 | Started production of Synthetic Quartz Crystal. |

| July 2003 | Incorporated with former Injex Corporation. |

| April 2005 | Changed the company name to Epson Atmix Corporation. |

| November 2007 | Transference consolidating of Suwa factory in Hachinohe factory. |

| June 2009 | Pharmaceutical Affairs Act authorization acquisition. |

| August 2012 | Amorphous alloys producing powder line increase. |

| September 2013 | Metal powder production factory "Kita-Inter Plant" completion. |

| January 2014 | Headquarters shelter public welfare building completion. |

| December 2017 | Completed construction of the amorphous alloy powders manufacturing plant (Kita-Inter Plant). |

| May 2019 | Expanded the amorphous alloy powder production lines of the Kita-Inter Plant. |

| October 2019 | Completed a new building at the Kita-Inter Plant. |

| October 2020 | Added new superfine alloy powder production lines at the Kita-Inter Plant. |

| June 2025 | The “Kita Inter Second Plant,” responsible for metal recycling, has been completed. |

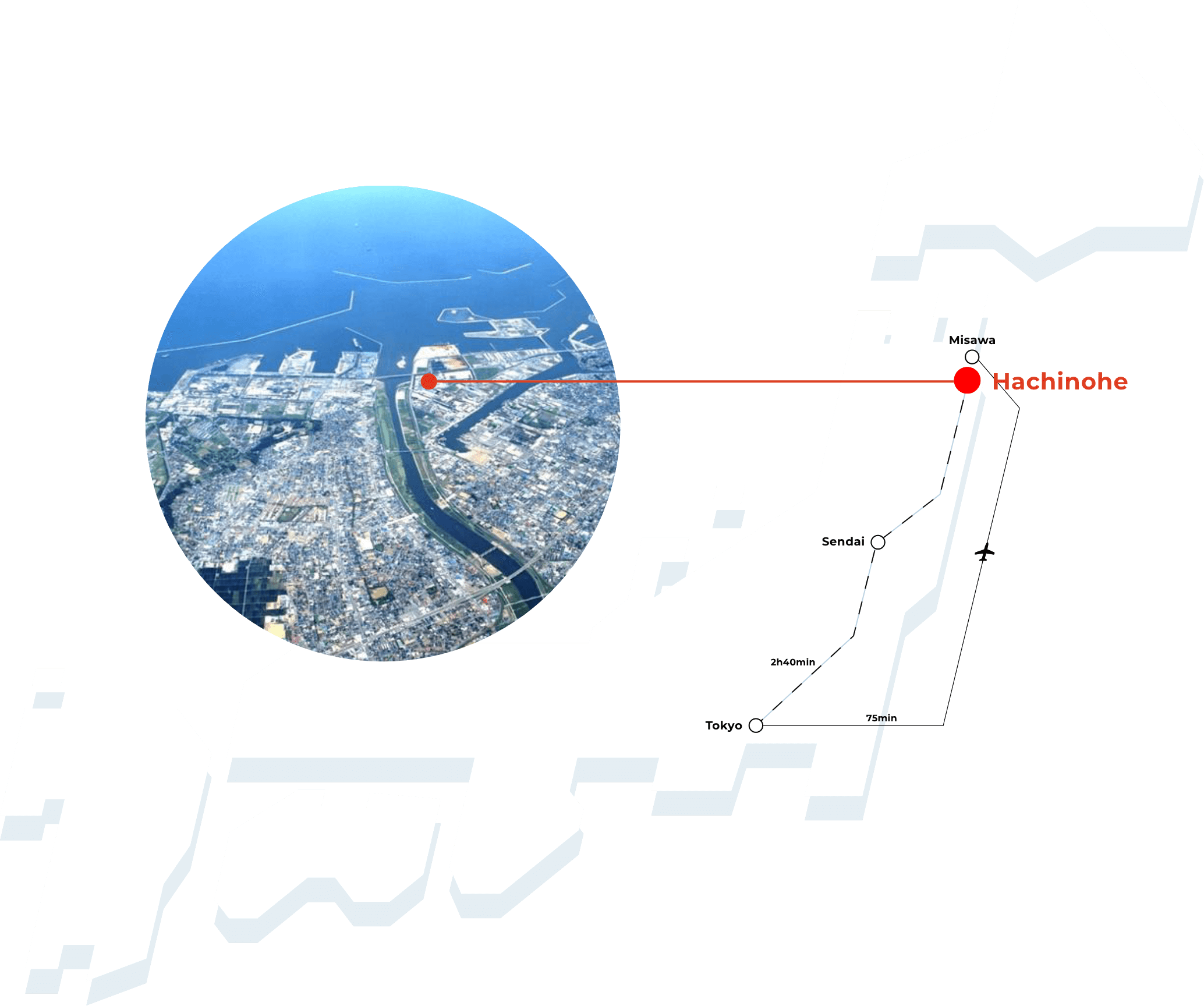

Access

Headquarters

4-44 Kaigan Kawaragi Hachinohe Aomori 039-1161 Japan

TEL:0178-73-2801

| Airplane |

Misawa Airport(40 minutes by taxi from Misawa Airport) Misawa Airport JR Misawa Station-JR Hachinohe Station(20 minutes by taxi from JR Hachinohe Station) |

|---|---|

| Shinkansen | JR Hachinohe Station(20 minutes by taxi from JR Hachinohe Station) |

Kita-Inter Plant

2-1-60 Kita Inter Kogyo Danchi Hachinohe Aomori 039-2245 Japan

TEL:0178-29-1112

| Airplane |

Misawa Airport(35 minutes by taxi from Misawa Airport) Misawa Airport JR Misawa Station-JR Hachinohe Station(20 minutes by taxi from JR Hachinohe Station) |

|---|---|

| Shinkansen | JR Hachinohe Station(20 minutes by taxi from JR Hachinohe Station) |

Kita-Inter Plant No.2

4-3-28 Kita Inter Kogyo Danchi Hachinohe Aomori 039-2245 Japan

TEL:0178-85-0535

| Airplane |

Misawa Airport(35 minutes by taxi from Misawa Airport) Misawa Airport JR Misawa Station-JR Hachinohe Station(20 minutes by taxi from JR Hachinohe Station) |

|---|---|

| Shinkansen | JR Hachinohe Station(20 minutes by taxi from JR Hachinohe Station) |

Philosophy